Instead of popping a cake in the oven, people may soon be able to pour cake batter in a 3D printer and watch the machine create the cake for them.

3D printing, also known as additive manufacturing, has come a long way since the early 1980s, when a tiny plastic cup became the first-ever 3D printed object. From then until now, the scope of 3D printing has expanded so much that even 3D food printers are available to the public.

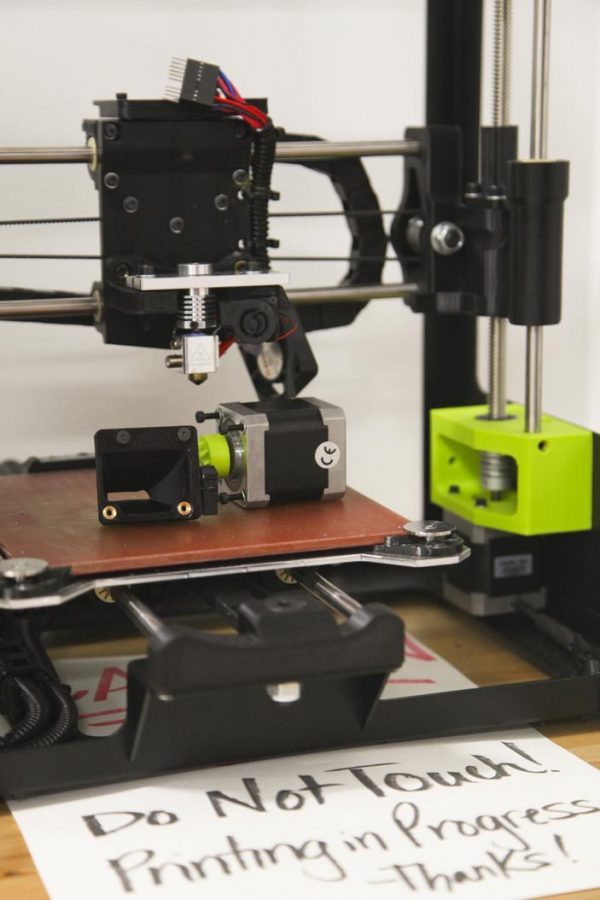

A standard 3D printer lays down thousands of layers of plastic, metal powder or other such materials to match whatever design the user inputs.

At Pitt, there are three cutting-edge metal printers in the additive manufacturing lab and several less expensive plastic printers spread out around the rest of campus, which students and faculty can use for various projects or research. Because Pitt already made these investments into traditional 3D printers, the University doesn’t currently print food and has no plans to in the near future.

Minking Chyu, who works in Pitt’s additive manufacturing lab, is optimistic about the future of 3D printing, though he said the technology is still emerging.

Chyu, a professor in the Swanson School of Engineering, said the mass production of 3D printed food is currently not viable from an economic standpoint, citing the $331,000 price tag of a lab-grown burger prototype developed at Maastricht University in the Netherlands in 2013.

“There’s a long way to go. Currently, 3D printers — especially for industrial application — are dealing with low volume, high cost components,” Chyu said.

Printing food is a complicated process compared to other kinds of 3D printing because multiple ingredients with different consistencies and melting points have to work together. As a result, food printers haven’t been around for as long as their plastic-based counterparts — the first consumer-grade food printer debuted in 2014, while the first plastic printer was sold in 1988. The aviation industry has used 3D printing to create and install airplane parts and French instructors are teaching sex education using printed models of sex organs.

3D printed food can be designed to look like standard-made food, such as burgers, or manipulated into a desired shape or design, such as an intricate, flower-shaped pancake. Regular food ingredients are mashed into a gel or paste and deposited into the 3D printer, which can reconstruct the food in any programmed shape.

For instance, to make bread, the user would put dough into the 3D printer, which would “print” the dough into the shape of a loaf of bread. For simpler ingredients, like chocolate or crystallized sugar, the printer can create intricate designs in nearly any pattern the user chooses.

Jessica Tillia, Pitt nutrition instructor, said in an email statement that she doesn’t know if the concept has potential to become anything more than an interesting gimmick.

“3D food printing does not seem very promising, in my personal opinion,” Tillia said in an email. “At first glance, I thought 3D food printing made food out of thin air, but the reality is that someone still needs to supply the food.”

Because of the behind-the-scenes work that goes into 3D printing food, Tillia questioned why 3D printed food would be used over traditional food.

“I think the bottom line is, if someone would go through the trouble to get the food … why would they not just assemble it themselves?” Tillia said.

Tillia also noted that proper storage and preparation of 3D food printer ingredients is vital to safety, just like with any type of food. Many have expressed concern that 3D printed food may be adulterated or nutritionally inferior to traditional food. As long as 3D printed food is made from healthy and safe raw ingredients, 3D printed food will be safe as well, since the process only changes the shape of the ingredients.

Other universities, however, have invested in 3D food printing programs and research. In 2015, the Culinary Institute of America announced that it was partnering with a 3D printing corporation to begin a beta program for “a culinary 3D printer.” In 2014, a team of three Michigan Institute of Technology students modified a commercially available printer so it could print ice cream.

There are several different types of food printers, which typically specialize in different types of food. For instance, the 3D Systems ChefJet crystallizes fine layers of sugar into geometric patterns like cubes and hollow spheres. Many commercial food printers are still in the late stages of their development and have yet to launch.

The Pancakebot is one of the few 3D food printers currently available to the public. It prints customizable pancakes and costs $299.

Though Chyu said he does not know of any 3D food printing projects at Pitt, he said the work he and his fellow scientists are doing in the additive manufacturing lab will benefit 3D printing technology of every kind.

“It all comes down to one essential question: cost. We need to get to the point where we can print food in a cost-effective way,” Chyu said. “We’re studying the nature of the additive manufacturing process, analyzing it using computer simulation techniques … That’s how we’ll get there.”

Chandler Mitchell, a server at Stack’d, had doubts about the quality of 3D printed food because, he said, it doesn’t sound appetizing. However, Mitchell, a junior biology and history and philosophy of science major, said he’s not worried that 3D printers will take the human element out of food preparation.

“With every technological advancement, there’s always fear of change, but they always create more jobs. Look at the Industrial Revolution, for example,” Mitchell said. “We’re not going to kick chefs out overnight.”