Pitt students reach new heights with NASA

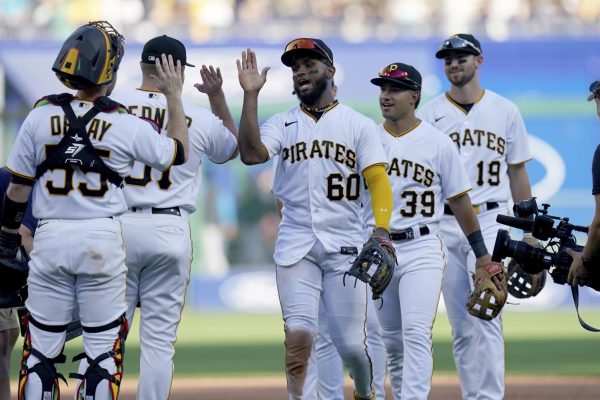

Photo courtesy of Marissa Defallo

NASA’s Student Spaceflight Experiments Program chose Pitt students Marissa Defallo and Nikolas Vostal’s aluminum corrosion experiment to fly this summer to the International Space Station onboard a SpaceX Falcon 9 rocket.

February 17, 2020

While many college students spend their summer waiting tables, two teams of Pitt students will be at Cape Canaveral watching experiments they designed fly to the International Space Station.

When Marissa Defallo, a junior mechanical engineering major, worked at American Airlines for her engineering co-op, she spent a lot of time working with aluminum. Airplanes, as well as satellites, are made of the material because it is lightweight and flexible. When looking for an experiment to be performed onboard the space station, she instinctively began to think about the material that makes up the better part of the satellite — aluminum.

As a student in Pitt’s Swanson School of Engineering, Defallo heard early on about NASA’s Student Spaceflight Experiments Program when Pitt’s engineering and pharmacy schools began recruiting for the project in September 2019. SSEP is open to students across the world, and 3,076 teams submitted proposals. Defallo showed up to the meetings without a team and found Nikolas Vostal, a junior material science and engineering major, in the same position. Together, they were able to come up with the winning idea.

Making use of Defallo’s aerospace work experience and Vostal’s material expertise, they decided on an aluminum-corrosion experiment. When radiation from the sun travels through the Earth’s atmosphere, it separates the atoms within molecular oxygen — molecules made of two or three oxygen atoms — creating reactive atomic oxygen that could compromise the structural integrity of the aluminum in an airplane or rocket when the two substances interact. The aluminum can become pitted — creating tiny holes that weaken the material. If a plane, satellite or rocket was compromised mid-flight, it could cause tears in the aluminum, which would be disastrous for any people or instruments on board.

After months spent on planning, research and design and three review boards, NASA chose Defallo and Vostal’s aluminum-corrosion experiment to fly this summer to the space station onboard a SpaceX Falcon 9 rocket. Pitt students Samantha Bailey, Jordan Butko, Amanda Carbone and Prerna Dodeja’s project on silver nanoparticles was also chosen for flight, along with 31 other experiments. Both teams will travel to Cape Canaveral, Florida, for the launch, scheduled for Aug. 5 at the latest.

Sachin Velankar, associate professor of engineering, assisted Defallo and Vostal with their project. But Velankar said he had a limited role in the project, and the students had control of everything.

“[I] provide whatever resources are needed for the project,” Velankar said. “I think of myself as a consultant, more than a scientist, in this case.”

According to Defallo, it is crucial to anticipate the corrosive effects of oxygen on aluminum before launch.

“The whole point of this project is to see how aluminum corrosion is in microgravity,” Defallo said. “That can tell us, potentially, if things like satellites or the space station would corrode quicker or slower or if [aluminum] topographies could even influence that.”

Topographies refer to the shape of the surface of the aluminum. Vostal came up with the idea to 3D-print the aluminum, allowing them to choose custom made topographies — including a wavy surface, rough surfaces and one smooth surface — for the experiment. In addition, a saltwater solution will be used to corrode the aluminum, so Defallo and Vostal can understand how the water will move in microgravity. While saltwater will not be corroding satellites in space, the oxygen in water and the harsh salt will create a similar effect.

“The perspective from material science is trying to understand why having a different surface could influence the rate of corrosion or where corrosion is most present,” Vostal said. “We really tried to … understand the fluid mechanics and how it also plays a part in the corrosion.”

Student experiments flying to the space station must be confined to a 10-milliliter silicon tube, placing major constraints on what can fly. Anything that might interact with the silicon — such as chlorine and other halogens — and could prove harmful to the astronauts are not allowed onboard.

According to Vostal, their experiment will mirror the one taking place on the space station, but it won’t be an exact match. The aluminum Vostal and Defallo are using is a different alloy than the one used on planes and satellites. Additionally, Vostal said, oxygen is the main corrosive in the atmosphere, but they are using salt water as an additional corrosive to simulate the environment.

“It’s sort of a proxy experiment,” Vostal said. “Something close to what corrosion would be like in space.”

However, Defallo doesn’t think the experiment will be so different that the results aren’t meaningful — that is, she still believes her project will give insight to the corrosion of aluminum in microgravity.

Next, Defallo and Vostal must wait for approval on their final design from NASA toxicology. Once the project has been cleared, they will receive their silicon tube and begin to order parts, making their long-planned experiment a reality.

While their project is aboard the space station, Defallo and Vostal will conduct the same experiment on Earth as a standard to compare their space results against.

The team members said they are looking forward to seeing their project go to space. Vostal is excited to be a part of experiments that may have a real influence on the future of space travel, and Defallo loves the experience, as she hopes to one day work for NASA or SpaceX.

“It’s a big deal,” Defallo said. “I need as much hands-on space experience as I can get. The more knowledge I have about space the better.”