The fermentation process of alcohol

April 11, 2019

Alcohol is a drink of choice for many contemporary college students. But according to Linda O’Reilly, a biological sciences lecturer at Pitt, the process of creating alcohol can be dated back more than 5,000 years ago.

“It’s been known since ancient times, ancient Egyptians stomped on grapes, allowed them to ferment and drank the product,” O’Reilly wrote in an email.

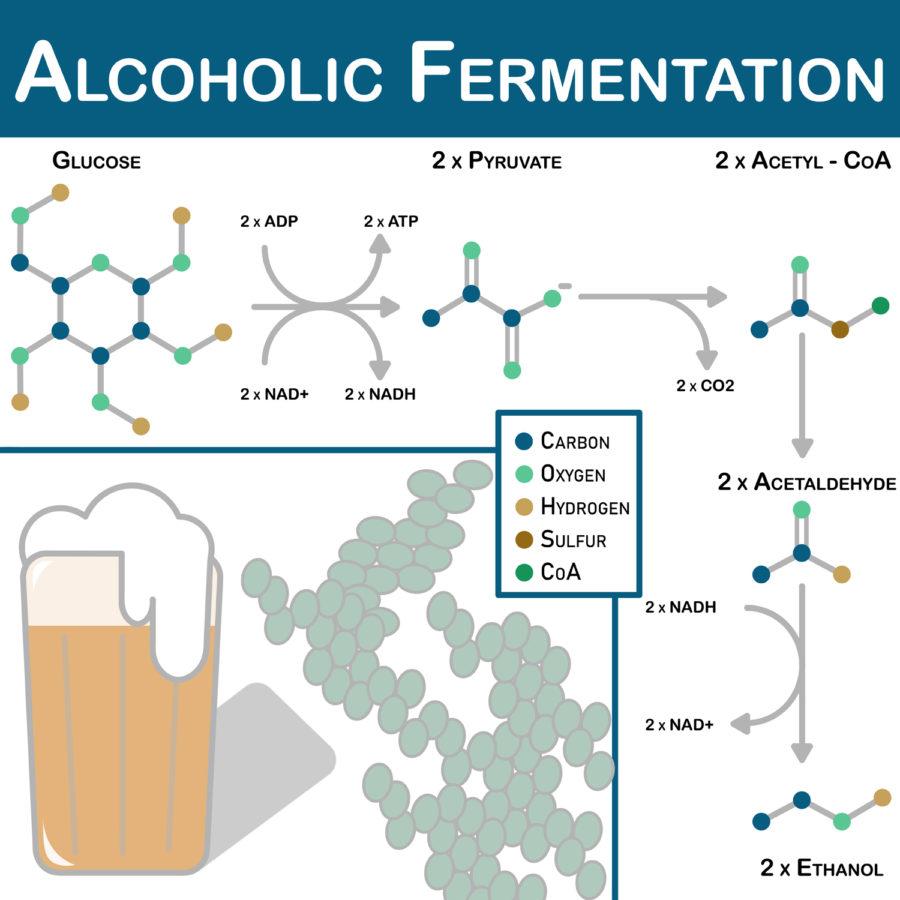

The process to create alcohol, collectively known as fermentation, is a complex biochemical process that starts from a simple ingredient found in everyone’s kitchen — sugar. The alcohol byproduct that is created during fermentation is used in drinks such as beer and wine.

But while we use alcohol for consumption purposes, micro-organisms — such as yeast — that create the beer and wine we love to drink use the pathway that produces alcoholic substances for energy.

“The goal of the yeast is to extract the energy from sugar. The production of alcohol is actually a byproduct, and not as useful to the organism as the energy produced,” O’Reilly said.

According to Jeffrey Brodsky, a biology professor at Pitt, many sugar-rich materials can be metabolized by yeast to produce ethanol. And different foods can produce the myriad alcohols available in liquor stores.

“If you use potatoes, you get vodka. If you use rye grain, you get rye whiskey. Barley, corn mash, yeast will eat all of them,” Brodsky said. “They didn’t really have to mix the yeast with these products, as a lot of yeast are living in nature on these products.”

But fermentation isn’t unique to yeast. In fact, humans go through this process as well — but only as a last resort. Humans usually produce energy through aerobic pathways, since we breathe air. However, when air is thin and there’s not enough oxygen to go through the aerobic pathway, our bodies automatically switch to anaerobic pathways such as fermentation.

“The problem is when oxygen becomes limiting, there is no oxygen to be the terminal electron acceptor, the whole chain shuts down and the organism would have no way to make essential cellular energy and would die,” O’Reilly said.

But anaerobic respiration is less efficient than aerobic respiration — it produces less energy from the same starting molecule. That’s why it’s only used as a last resort.

“[The process] is not very efficient at extracting the energy as the glucose is only partially broken down, but when the only option is death, it’s better than nothing!” O’Reilly said.

According to Brodsky, anaerobic respiration in mammals produces lactic acid instead of ethanol. Lactic acid fermentation happens when you’re out of breath while you’re running and your muscles begin to burn.

Brodsky also explained a theory that proposes a reason why yeast evolved to produce alcohol instead of something like lactic acid. He said it could be due to the antibacterial properties of ethanol.

“[Yeast] may have evolved this pathway, not just as a means to survive under non-optimal growth conditions, but actually as a way to ensure that they sort of win in the microbial environment,” Brodsky said. “Because yeast is a primitive fungus, they have a very sturdy cell wall so the ethanol doesn’t hurt them. But it can hurt other microbes that may not have such a sturdy cellular wall or barrier.”

Xinyu Liu, an assistant professor of chemistry, said food industries are not the only users of the ethanol produced by yeast. Liu said ethanol also has significant promise as a biological source of fuel.

“The gasoline sold in the U.S. is almost 20% ethanol. So a lot of this ethanol is obtained by fermentation,” Liu said. “It’s basically an alternative to using fossil fuels. It just converts biomass — plants which you can grow — and is renewable.”

Liu said scientists are also looking at potential genetic modifications to yeast that would make ethanol production a more economic procedure.

“Let’s say you can engineer a yeast that is more tolerant in the heat or more tolerant to other things. That can make the fermentation process faster,” Liu said. “If you can fully convert a piece of corn in a day rather than a week, that’s economically very important.”